A 12-pulse diode bridge rectifier is an electrical circuit that converts alternating current (AC) input into direct current (DC) output with reduced harmonic distortion. It is a specialized rectifier configuration used to supply a cleaner and more stable DC voltage in high-power applications. The term “12-pulse” refers to the fact that this rectifier design utilizes two separate six-pulse diode bridge rectifiers operating in parallel but with a 30-degree phase shift between them. Here are the key features and components of a 12-pulse diode bridge rectifier:

-

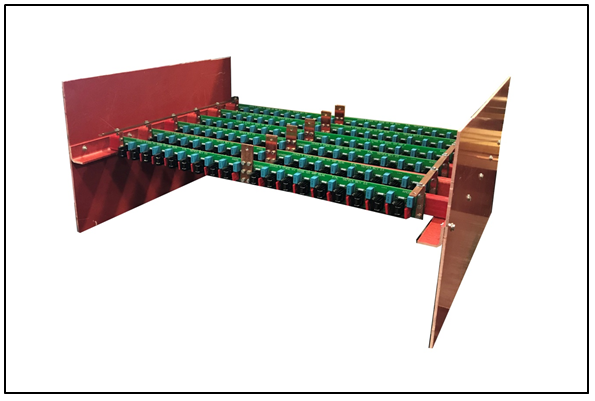

Diode Bridge Rectifiers: Two six-pulse diode bridge rectifiers are used, each consisting of six diodes arranged in a bridge configuration. These diodes allow current to flow in only one direction, effectively converting the AC voltage to a pulsating DC voltage.

-

Phase-Shifting Transformers: A pair of phase-shifting transformers is used in the system to introduce a 30-degree phase shift between the input currents of the two diode bridge rectifiers. This phase shift is crucial for reducing harmonic distortion in the input current waveform.

-

AC Input: The 12-pulse diode bridge rectifier is connected to the AC input, typically through a delta-wye (Δ-Y) transformer connection. The input voltage is stepped down or up as needed by the transformer.

-

Filtering Components: After rectification, the pulsating DC voltage is smoothed using filtering components such as capacitors and inductors to reduce ripple and provide a more stable DC output.

-

Load: The load, which can be a motor, drive, or other high-power device, is connected to the output of the rectifier to receive the DC power supply.

Key Benefits and Applications:

-

Reduced Harmonic Distortion: The 12-pulse diode bridge rectifier configuration significantly reduces harmonic distortion in the input current compared to standard six-pulse rectifiers. This is important for applications where minimizing harmonic interference on the power grid is essential.

-

High Power Applications: The 12-pulse rectifier is commonly used in high-power industrial applications, such as motor drives, variable frequency drives, and industrial processes requiring precise and low-distortion DC voltage.

-

Power Quality Improvement: It improves power quality by reducing harmonics, which can cause voltage waveform distortion and affect other connected equipment.

-

Adjustable Output: Depending on the specific application, the DC voltage output of the rectifier can often be adjusted by controlling the transformer tap settings or by using voltage regulation methods.

-

Industrial Motor Control: The 12-pulse diode bridge rectifier is frequently used in motor control applications to provide a clean and stable DC supply for driving industrial motors, ensuring smooth and efficient operation.

It’s worth noting that while the 12-pulse diode bridge rectifier configuration offers advantages in reducing harmonics and improving power quality, it also requires additional components, including phase-shifting transformers, which can increase the complexity and cost of the system compared to standard rectifiers. Consequently, its use is typically reserved for high-power applications where harmonic distortion reduction is critical.